|

These are pictures

taken during the Green Rover's engine, transmission and power steering

conversion. This page represents a quick pictorial overview. I have

written a page describing the engine

swap in detail and one describing the power

steering conversion in detail.

All the fabrication work was done by Timm Cooper, then of Medford

Oregon. The transmission to transfer case adapter was designed

and fabricated by Timm Cooper. I did a lot of wrench turning, the

hydraulic line fabrication and the rewiring.... Oh, and a lot of

parts cleaning.

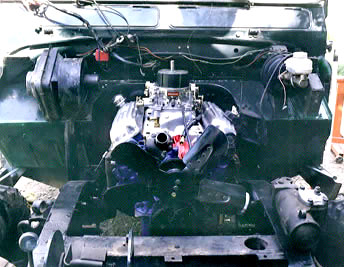

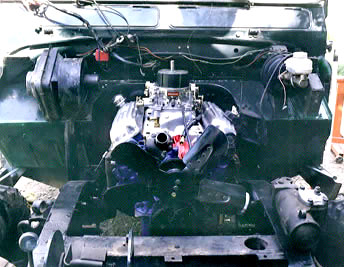

Stripped and ready for the swap

The front body clip, engine and transmission have been removed.

The battery box and engine mounts were removed soon after this picture

was taken. Pay attention to the shape of the bell housing cutout

in the bulkhead. The right half (picture left) of the bell housing

cutout will be removed, moved over 7.6 cm (3 inches) to the right

(picture left) and rewelded. A flat steel patch was welded between

sections. This widened the bell housing cutout in the bulkhead to

allow the engine to be centered in the frame.

Engine Mounted

Notice the new location of the right side bell housing cutout in

the bulkhead. Moving the side of the cutout 10 cm to the right brought

the edge of the cutout to the edge of the Kodiak heater mounting

flange. The heater and the inside ducting remained in their original

positions. The engine is 2.5cm (1 inch) to the left of being centered

in the frame.

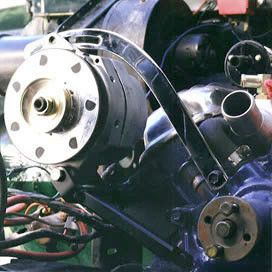

Side of engine

The radiator cross member has been moved forward 2.5cm (1 inch)

to provide clearance between the mechanical fan and the radiator.

The lower tank of the radiator will fit behind the cross member

between the frame rails. The cross member front tabs were shortened

and the mounting holes were redrilled one inch rearward so that

the radiator bulkhead would remain in its stock location. The cross

member seen in front of the radiator cross member is the rear mount

for the Mercury winch.

Note the exhaust manifold. It is the left side exhaust manifold

from an early sixties V8 Ford Falcon. This manifold type was mounted

on both sides. The bottom tilts inwards away from the frame.

Left mounting bracket

The frame mounts were modified and moved forward. Stock Land Rover

engine mounts were used. New steel brackets were fabricated on

the engine side of the Rover mount. Note: In real life the

engine Mounts Timm installed were not up to real life use. A

set of the stronger diesel 2.25 engine mounts never lasteed more

than hale a year and I finally paid another company to build new

rame mounts and install a set of Ford small block mounts

designed for desert racing Broncos.

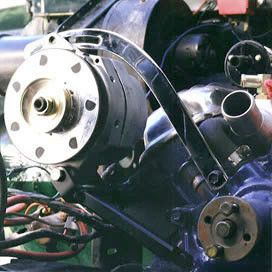

Power steering pump and mount

A Saginaw "canned ham" type steering pump was used because it is

believed to be more reliable than the Ford steering pump. This one

came off a 1980 International Scout. This pump was commonly used

on GM cars. The bracket was modified from an early Ford small block

power steering pump.

Alternator Bracket

A high amp Delco alternator was used since The Green Rover was

already wired for a Delco. The Alternator was mounted as high as

possible on the engine to keep it above water while wading. The

top mounting bracket is a GM V8 alternator top bracket. The lower

bracket was fabricated from scratch.

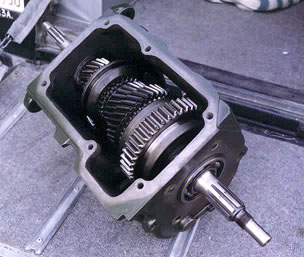

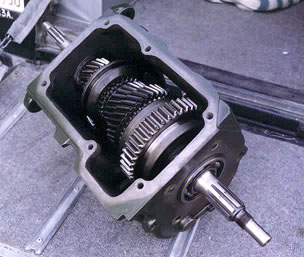

Borg Warner T-18 transmission

This T-18 gearbox has the rear output shaft reworked to fit the

Land Rover output gear and transfer case. This is a key part of

Timm Cooper's T-18 to LR transfer case conversion. The large gear

is the Granny first gear. With the stock series 4.7 ring and pinion

the first gear provides a 70:1 low range rock crawling ratio. The

T-18 transmission is available in both close ratio and with a granny

first. It does not have syncro in first gear. The T-19 is the all

syncro version of this gearbox. The T-18 and 19 gearboxes were widely

used and highly regarded as a strong trouble free light truck transmission.

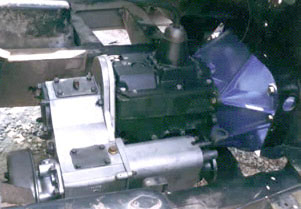

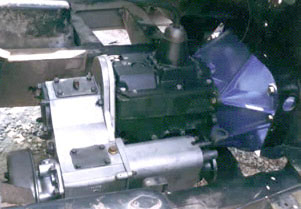

Mounted in place

Here you can see the reworked T-18 gearbox sandwiched between a

stock Ford bell housing and the stock Land Rover transfer case.

There is a thin metal adapter plate between the gearbox and the

transfer case allowing them to be bolted together.

The Transfer case is in it's stock front to rear location but was

moved to the right when the engine was centered in the frame. The

steel transfer case mounts attached to the transfer case were modified

for the difference in location. The stock LR rubber mounts and frame

mounts remained unmodified. There is a bell crank that mounts inside

the right frame rail that pulls the lever on the emergency brake.

This bell crank had to be modified for the new lateral location

of the emergency brake.

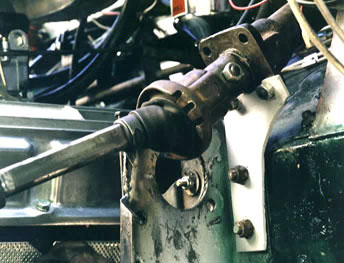

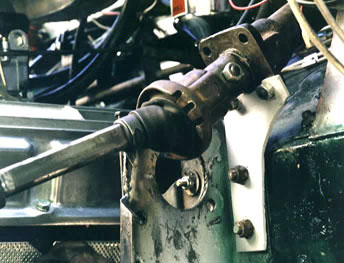

Clutch slave cylinder

The stock Series II clutch slave cylinder was used. A mounting

bracket was fabricated out of the original mounting bracket. The

Ford throw out bearing release lever was modified to fit the stock

Land Rover slave cylinder rod.

Power steering

A Saginaw power steering box from a 1980 International Scout was

used.

Power steering box mounted into place

The power steering box is mounted on the outside of the frame rail.

Note the front of the box is right behind the radiator bulkhead.

The box is placed so that the bottom is forward of the axle housing

and the suspension stops. The stock mounting tab for the front brake

was cut off for clearance. There is an unused hole at the bottom

of the tab that is the correct size for mounting the flex hose connection.

It has the advantage of providing additional slack in the brake

line to handle increased articulation.

The Scout pitman arm was shortened to work on the Rover. The stock

length provides approximately 2-1/2 turns lock to lock. The arm

was shortened and a new hole was drilled at 8-1/2 inches then reamed

out to fit the Land Rover tie rod end. This provides just under

4 turns lock to lock. This is just slightly faster than D110 power

steering.

A new larger diameter drag link was fabricated using the ends of

the original link. This provided an increase in arm strength.

Mounting plate for steering box

The mounting plate is made of 3/8ths inch thick steel. Grade 8

nuts were welded to the back. Clearance holes were drilled in the

frame then the plate was welded to the frame. A 3/8ths inch steel

strap was welded to the frame bottom below the side bracket for

additional strength.

Steering column bracket

The steering column was unbolted from the box and reused. The worm

gear was cut off the bottom of the Land Rover steering shaft and

the end of a GM steering column was welded to the bottom of the

Rover shaft. When I asked about strength of the weld I was shown

where the original stock Land Rover steering shaft was composed

of three steel parts welded together from the factory.

A special bushing was machined to support the bottom of the shaft

in the bottom of the Land Rover steering column. A mount was fabricated

out of a steel plate to mount the lower column to the bulkhead.

The top of the flange on the old steering box mount was cut off

for clearance.

Collapsible GM steering shaft

A collapsible GM steering shaft with a 'U' joint at each end connects

the steering box to the steering column.

Return to page top

|